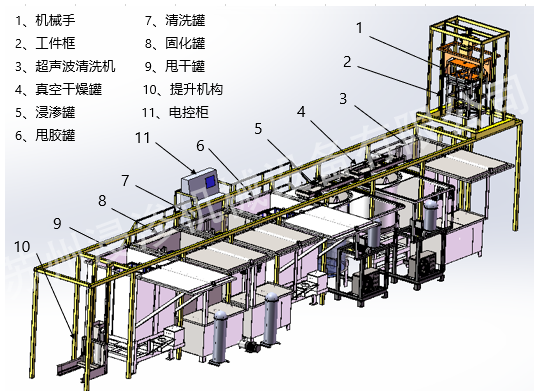

Schematic diagram of fully automatic reverse infiltration equipment

全自动翻转型浸渗设备

适合:机加工(多面螺纹孔)油污铸件和螺纹孔(M3以上)的机加工油污铸件,客户没有清洗设备同时产品表面清洁度要高的产品浸渗

设备特点:

采用超声脱脂和翻转喷淋系统,保证产品清洗比较干净

采用真空干燥节省干燥时间,提供高生产效率和节拍

采用六向离心脱液系统,能够把产品六个面的螺纹孔中浸渗剂离心甩干,相比传统四向离心脱液系统减少浸渗剂的消耗,节省成本,同时也为下一步的清洗提供有利的条件

采用翻转喷淋清洗系统,能够把产品六个面的螺纹孔清洗干净没有残夜,不再需要人工用气枪吹螺纹孔残液,由于人工吹不环保,人工气枪吹不能保证每次都能吹到每个孔(视觉疲劳)

设备投资稍大,节省人工很多,性价比非常高

采用PLC和机械手臂全自动控制,减少人工成本

Suitable for machining (multi thread hole), oil casting and threaded hole (M3) machining oil castings, customers do not have cleaning equipment, while cleaning products with high surface cleanliness

Equipment features:

1. 、 ultrasonic degreasing and reverse spraying system are adopted to ensure the cleaning of products

2. vacuum drying, saving drying time, providing high production efficiency and beat

3. to six by centrifugal dewatering system, can make the product six of the threaded hole infiltration agent centrifugal drying, compared to the traditional four centrifugal dewatering system to reduce infiltration agent consumption, save the cost, but also provide favorable conditions for the next step of cleaning

4. using the spray cleaning system, can make the product screw hole six surface clean no residual night, no longer need to use air gun to blow the threaded hole residual liquid artificial, artificial blowing air gun to blow the artificial environmental protection, can not guarantee that all can blow to each hole every time (visual fatigue)

5., equipment investment is slightly larger, saving a lot of labor, very cost-effective

6., PLC and mechanical arm automatic control are adopted to reduce labor cost

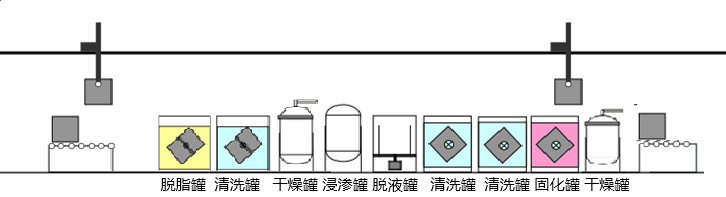

Equipment layout drawing